Customization sounds great on paper. Until you try to do it at scale. The truth? Personalization can quickly turn into a production nightmare—unless you rethink the way you do things.

Today’s textile brands face a growing demand for uniqueness. Buyers want something different, special, tailored. But how can you offer flexible textile customization without sacrificing efficiency, time or margins? Let’s just say… it’s possible. If you play it smart.

your customer wants it all (and fast)

Welcome to the age of ultra-choice. Whether it’s a specific shade, an exclusive pattern, or a limited edition colorway, your customers aren’t just browsing—they’re imagining. Their own version. Their own look. Their own product.

And that’s where the pain can start.

Because most textile production lines weren’t built for flexibility. They were built for repetition. Introduce too many options, and suddenly you’re juggling file versions, fabric approvals, and endless back-and-forths. Deadlines stretch. Costs explode. Everyone loses patience.

Customize the flow, not the workload

The problem isn’t customization. It’s friction.

The solution lies in flexible textile production—a setup that can adapt without chaos. That’s where digital tools, especially a robust textile personalization platform, become game changers.

The client sees the options. The system does the work behind the scenes: generating the right file, pushing data to the right supplier, updating visuals in real time.

You don’t need a new team. You need a smarter process.

Digital tools that work like an extra pair of hands

Today’s best platforms don’t just look good in a demo. They actually reduce workload.

3D visualization. Color simulation. Automated file creation. Seamless integration with production partners.

Every step is designed to make mass customization in fashion possible—and scalable.

And when you reduce physical sampling, automate repetitive tasks and centralize data?

Personalization becomes efficient. Predictable. Even fun.

From custom requests to smart production

On-demand textile manufacturing is no longer a pipe dream. It’s a viable way to produce what people actually want—without drowning in unused stock.

By moving from static production to dynamic, digital flows, you gain responsiveness. You test, adapt, and launch with minimal waste.

And that’s not just better for your margins—it’s better for the planet, too.

Personalization should simplify, not complicate

If your customization strategy is making things harder, it’s time to switch tools—not to give up.

A good platform helps you do more, with less hassle.

Your customers get a product they love.

Your team gets room to breathe.

And your business stays ahead.

Because in the future of textile, personalization isn’t a luxury. It’s the standard.

The only question is: will your production keep up?

What do textile brands really expect in 2026?

In 2026, textile brands expect more than style: they want transparency, digital...

Read more6 trends that will reshape textile sourcing in 2026

Discover the 6 key trends that will transform textile sourcing in 2026...

Read moreTop 5 digital innovations transforming the textile industry in 2025

Digital transformation is reshaping the textile industry. From AI-driven design to immersive...

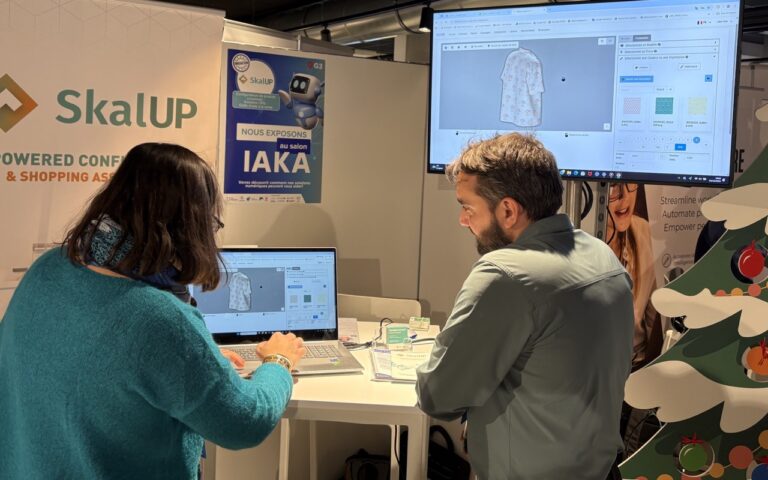

Read moreS2G XR awarded the Innovation Label at the IAKA Fair in Namur

Awarded at IAKA Fair in Namur, S2G XR receives the Innovation Label...

Read more